Beam, a leader in AI-driven technology services for offshore wind, has unveiled its latest innovation—SubSLAM X3. This cutting-edge underwater perception system is set to revolutionise the monitoring and maintenance of offshore wind farms, offering real-time, high-resolution 3D mapping to enhance underwater operations.

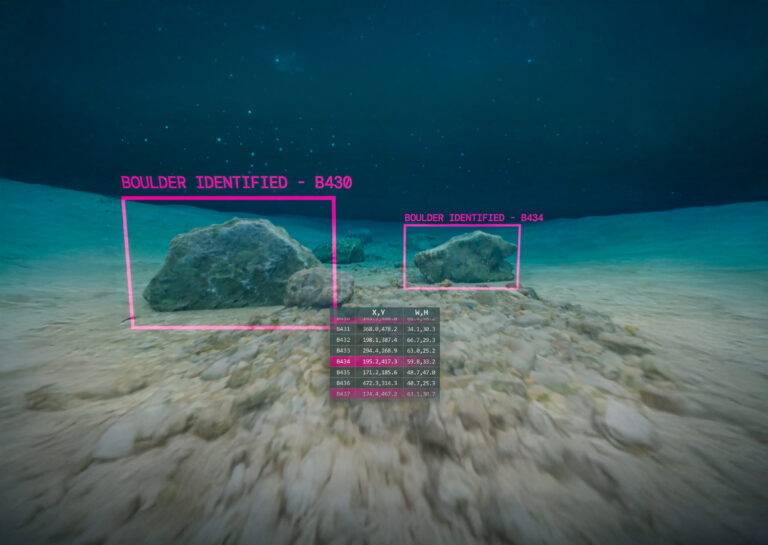

The SubSLAM X3 seamlessly integrates artificial intelligence (AI), robotics, and advanced simultaneous localisation and mapping (SLAM) technology, which allows for unprecedented precision in underwater work. This combination accelerates the development, construction, and maintenance of offshore wind projects, offering 4K video resolution and precise 3D reconstructions. This new capability means more efficient and detailed inspections of underwater assets and intelligent control of autonomous underwater vehicles (AUVs).

Compared to its predecessor, the SubSLAM X2, the X3 version offers significant upgrades. These enhancements improve the speed, accuracy, and visual detail of offshore infrastructure inspections. The newly released V3.0 software version boosts navigational assistance for operators working in difficult underwater terrains, while new features allow for easier capture of 3D models. The system’s improved integration with third-party sensors, like sonar fusion, also makes it more versatile across different environments and operations.

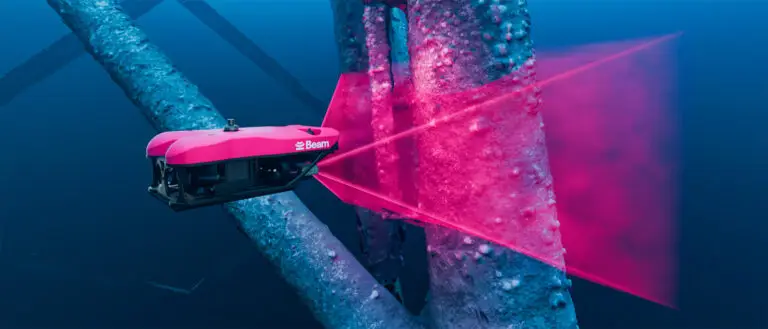

Despite its powerful capabilities, the SubSLAM X3 has a more compact, lightweight design, making it suitable for both smaller observation-class remotely operated vehicles (ROVs) and larger work-class ROVs. Capable of operating at depths of up to 3000 meters, it features enhanced sensors to deliver exceptional image quality even in low-light conditions. These advancements ensure reliable performance in challenging underwater environments.

According to Ross Hilditch, Senior Product Manager at Beam, SubSLAM X3 represents a leap forward in data collection and asset inspection for the offshore wind sector. “This system not only enhances our capabilities in terms of data collection and asset inspection, but it also significantly reduces the operational footprint required for such activities. It’s about doing more with less, safely and sustainably.”

The launch of SubSLAM X3 marks a significant step forward for offshore wind technology, pushing the boundaries of what’s possible in underwater inspection and maintenance. By combining advanced AI, robotics, and enhanced 3D mapping, Beam continues to lead the charge in driving efficiency, sustainability, and innovation in the renewable energy sector. With SubSLAM X3, the future of offshore wind has never looked clearer—both above and below the surface.