At Web Summit 2024, Beam introduced Scout, a revolutionary autonomous subsea robotic system designed to address key challenges in offshore wind inspection and maintenance. By leveraging advanced AI, 3D vision, and robotics, Beam is driving down costs and making offshore wind a more efficient and competitive energy source.

Brian Allen, CEO of Beam, highlighted the urgency of innovation in renewable energy: “It’s never been more important to find ways to cut costs and project timelines.”

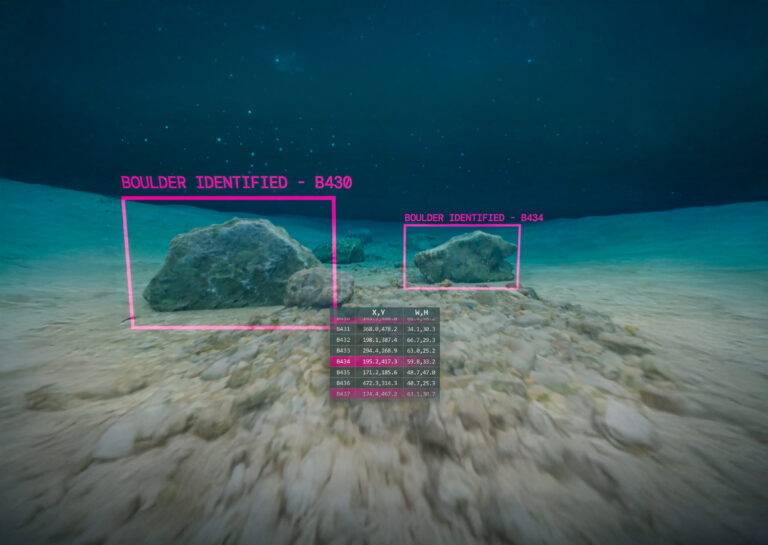

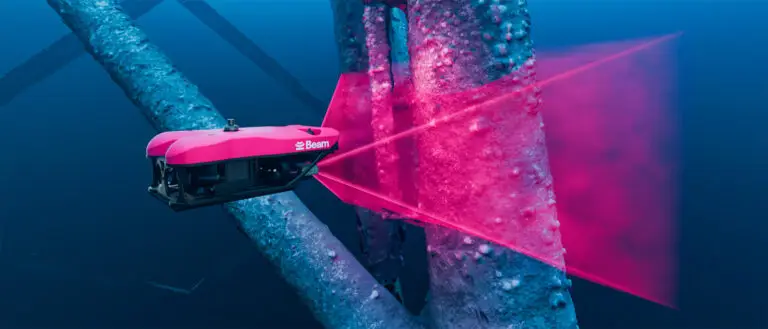

Scout offers groundbreaking capabilities, including 3D reconstructions, stereo 4K video, and precise navigation, which enable faster and more cost-effective inspections. According to Kari Dempsey, Beam’s CTO, the robot is the result of years of development: “The algorithms we are using now can assess any kind of infrastructure without having any prior knowledge of it. This gives Scout the ability to navigate and map the environment that it’s in.”

Scout processes data through Beam’s EdgeAI system, which packages information into smaller, actionable datasets that can be accessed via its Vaantage platform.

Joe Tidball, Executive VP of Service Innovation, explained how Scout could help alleviate the skills gap in offshore wind: “Governments are pushing offshore wind as a viable energy source, but not enough people are involved. In the UK alone there are only 30,000 people in UK offshore wind industries, and [for wind energy to be viable] we will need 100,000 by 2030. That’s 70,000 needed.”

By enabling inspections to be conducted directly by crew transfer vessel (CTV) teams, Scout simplifies operations and reduces reliance on large, specialist crews.

Beam’s innovations are designed to cut costs significantly for offshore wind operators. Speaking about the potential savings, Tidball noted:

“Scout’s AV reduces inspection time costs by ‘one or two orders of magnitude,’” making inspections far more affordable than traditional methods that rely on large vessels and extensive resources.

Scout also integrates with Beam’s digital twin capabilities, providing detailed 3D reconstructions of assets. Tidball emphasised the value this offers for ongoing maintenance:

“Energy firms will want to spend as little money as possible maintaining their assets – but they will still need to maintain them at quite a high standard.”