Internal monopile inspections

The internal inspection of monopiles is vital for maximising the lifespan of these assets. Leveraging state-of-the-art technology, our solutions help to prevent potential failures that can lead to unplanned shutdowns and revenue loss.

Meticulous, safe and efficient

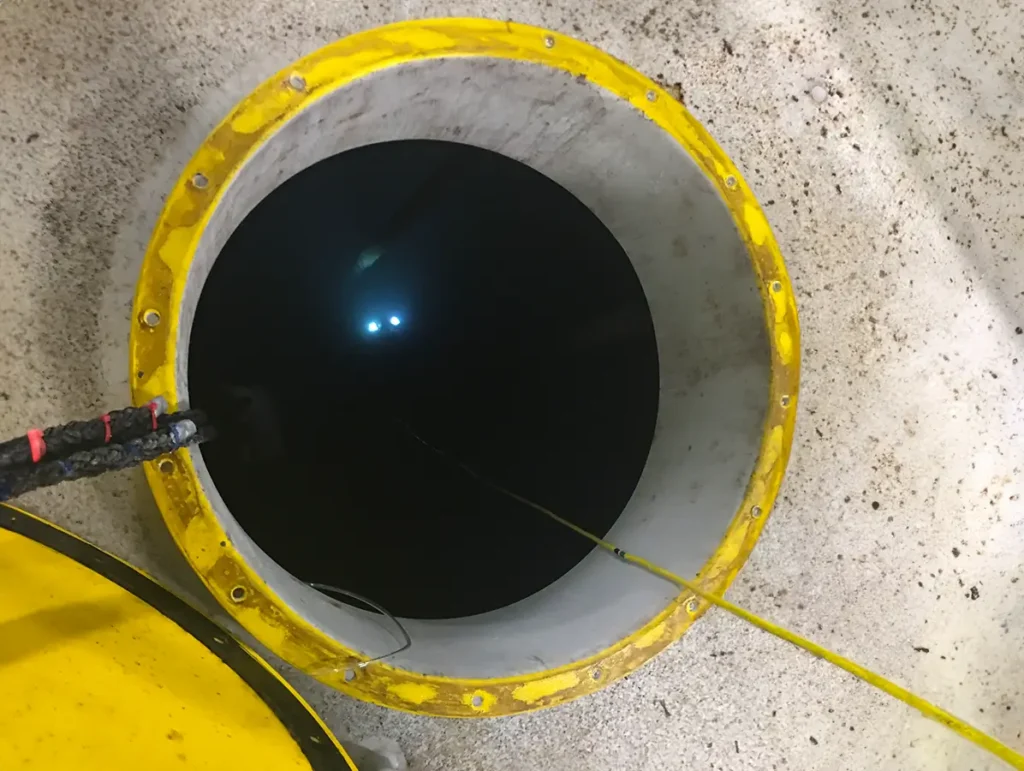

Our cutting-edge approach eliminates the need for personnel to enter confined spaces by deploying advanced robotic vehicles to achieve meticulous, safe and efficient results.

Powerful, compact ROVs

Utilise state-of-the-art compact ROVs to optimise inspection costs over traditional methods.

Reduced HSE exposure

Eliminate the need for personnel to enter confined spaces, reducing risks associated with human inspection.

GWO certified professionals

GWO certified professionals with a proven track record in conducting internal monopile inspections.

Prioritising safety, efficiency and precision

Our cutting-edge approach eliminates the need for personnel to enter confined spaces by deploying advanced robotic vehicles, such as the Mission Specialist Pro 5, designed to handle scopes with space and deployment speed constraints.

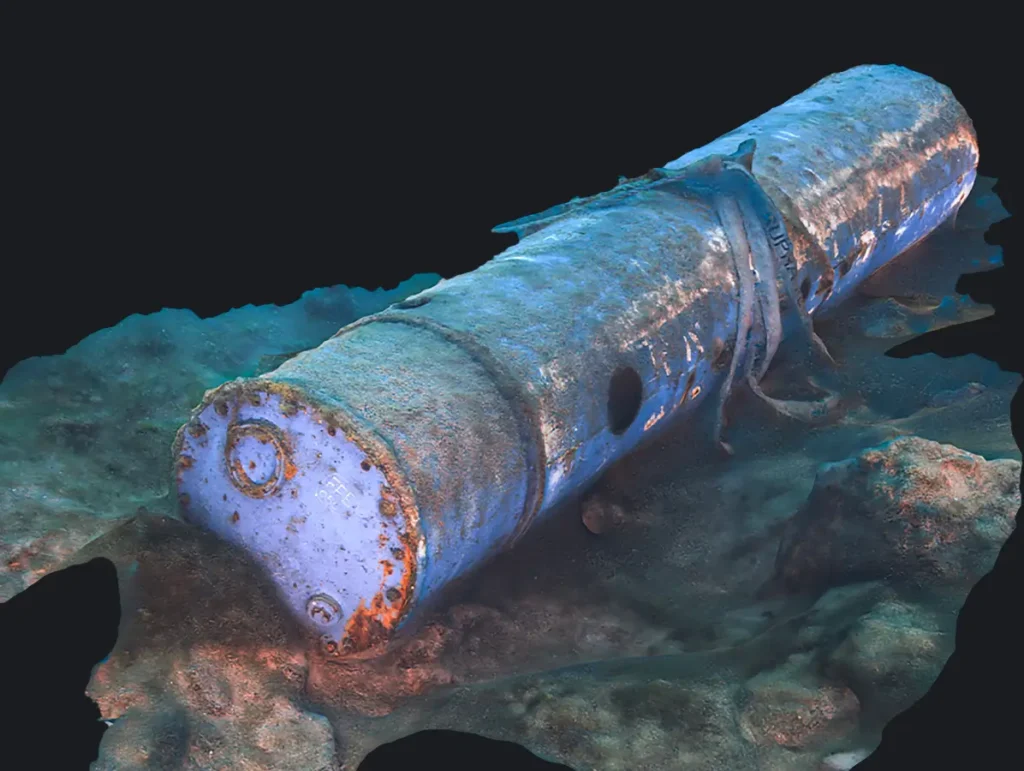

Equipped with state-of-the-art technology, our robotic vehicles navigate the internal monopile with precision, capturing the highest-resolution visual data and facilitating non-destructive testing. This innovative method not only enhances safety by reducing human exposure to confined spaces, but also ensures a meticulous examination of the monopile’s structural integrity with speed and efficiency.

Our visual inspections encompass every detail of the internal monopile, providing a detailed analysis of its condition. The non-destructive testing techniques employed go beyond the surface, identifying potential issues that may compromise the monopile’s functionality. This comprehensive approach allows us to detect anomalies, corrosion, or structural weaknesses, enabling timely and targeted maintenance interventions.

By choosing our internal monopile inspection services, you invest in a solution that prioritises safety, efficiency, and precision. With our commitment to leveraging cutting-edge technology, we deliver unparalleled insights into the health of your monopile infrastructure, ultimately ensuring the longevity and reliability of your assets.

Our added value

- Benefit from the expertise of our team, comprised of GWO (Global Wind Organization) certified professionals with a proven track record in conducting internal monopile inspections.

- Our solutions can be seamlessly deployed from wind farm operator’s assets, ensuring convenience and adaptability to various operational environments.

- Identify and address potential through-wall cracking on welds, providing a crucial assessment of the monopile’s structural integrity and preventing future complications.

- Eliminate the need for personnel to enter confined spaces, reducing risks associated with human inspection.

- Identify problems early on, enabling timely and targeted maintenance interventions to ensure the longevity of monopile infrastructure.

- Utilise state-of-the-art compact ROVs to optimise inspection costs over traditional methods.

A breadth of capabilities

Our specialist skills and knowhow have been hard-earned through challenging projects in the harshest environments. This has deepened our understanding of what technology is truly capable of, enabling us to deliver exceptional insights with speed and efficiency.

Downloads

Explore our collection of specification sheets and brochures to gain a deeper understanding of our technology and the services we provide. Download now to discover how our expertise can support your needs and drive your success.

Brochure

Operations & Maintenance

Vast industry knowhow combined with leading-edge

technology, capturing and delivering the highest quality

data to inform and de-risk your projects.

Specification sheet

Atom EV

The Atom EV is a compact high-stability, very high-performance electric work class ROV.

Specification Sheet

SubSLAM X2

Download the SubSLAM X2 specification sheet for more details.

View our latest news and highlights

Press Releases

Latest Business Update: Q1 2025

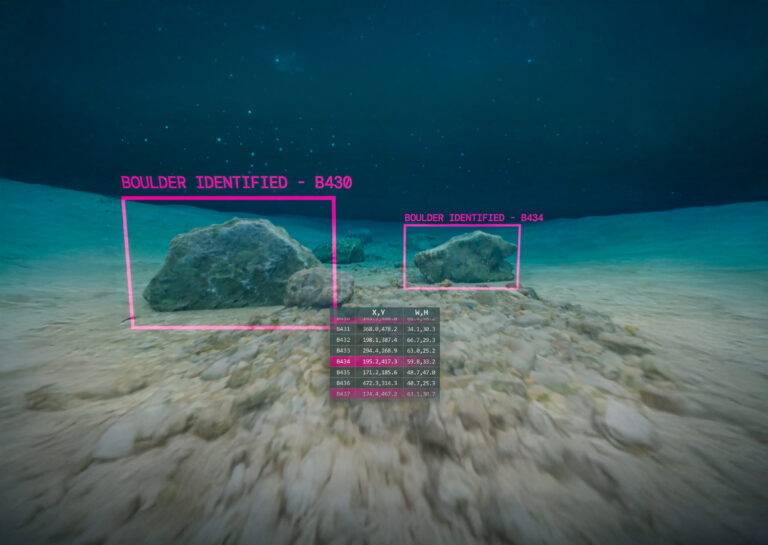

How machine learning and AI is making boulder picking 400x faster

We’ve Achieved Planet Mark Certification for a 3rd Consecutive Year

Beam Recognised Among Britain’s Fastest-Growing Tech Companies